| View previous topic :: View next topic |

| Author |

Message |

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Wed Mar 05, 2008 9:17 am Post subject: a box Posted: Wed Mar 05, 2008 9:17 am Post subject: a box |

|

|

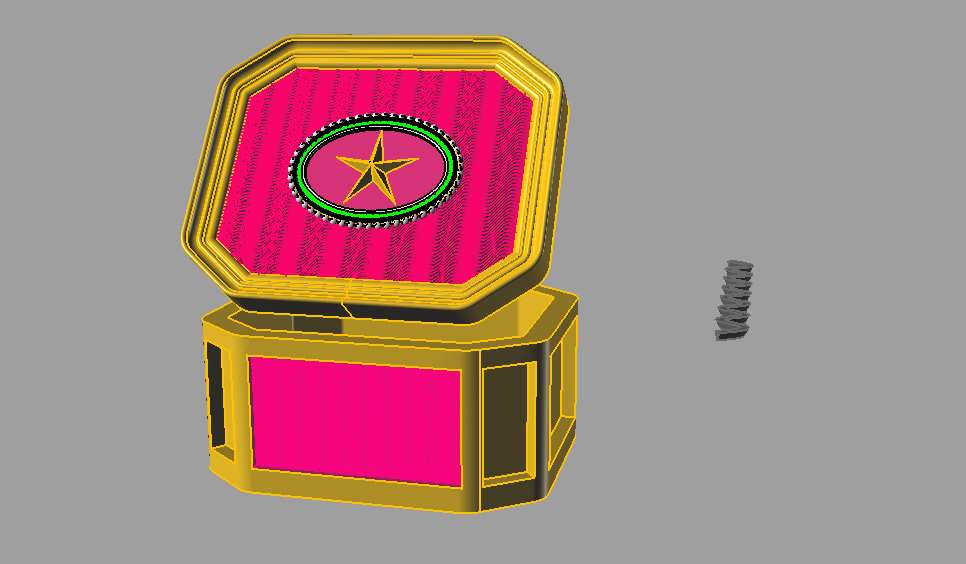

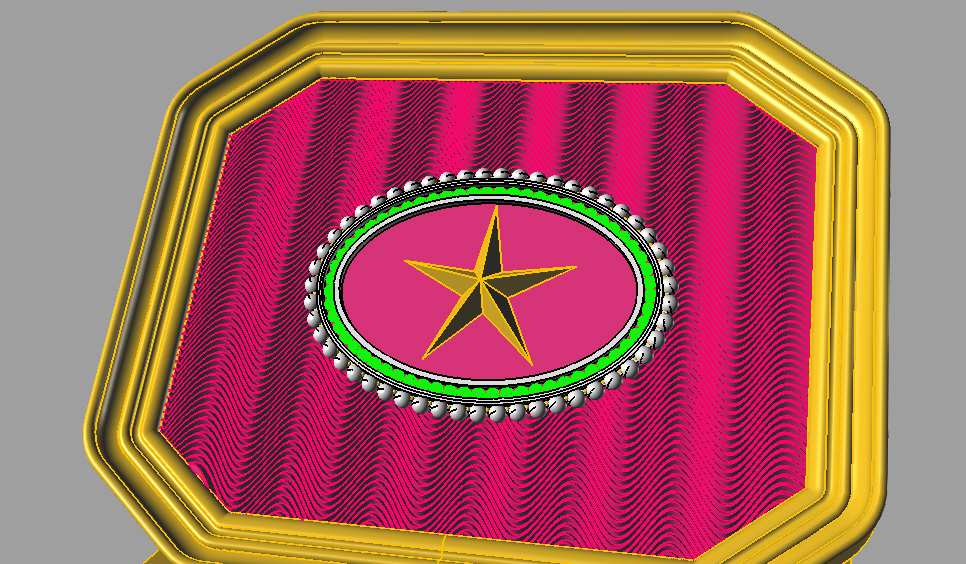

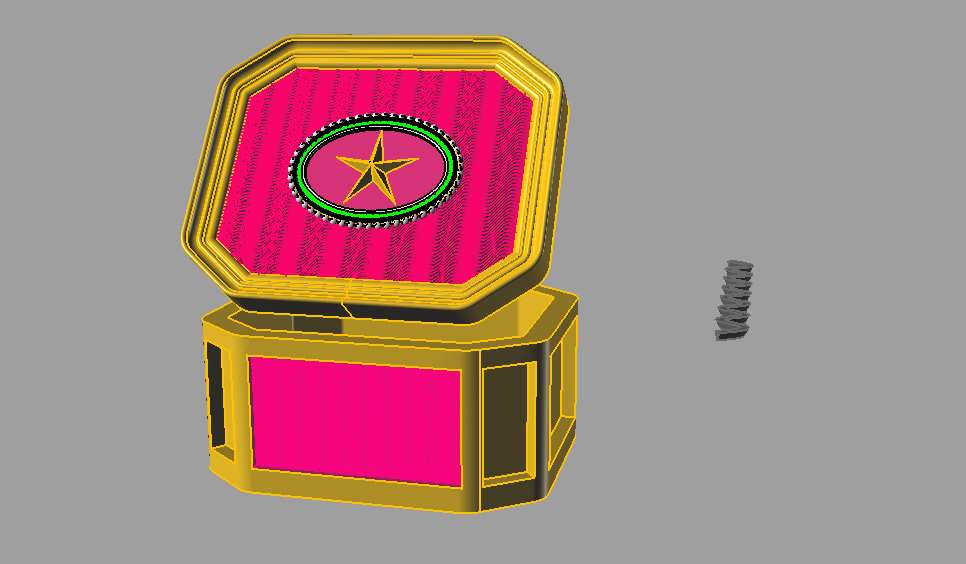

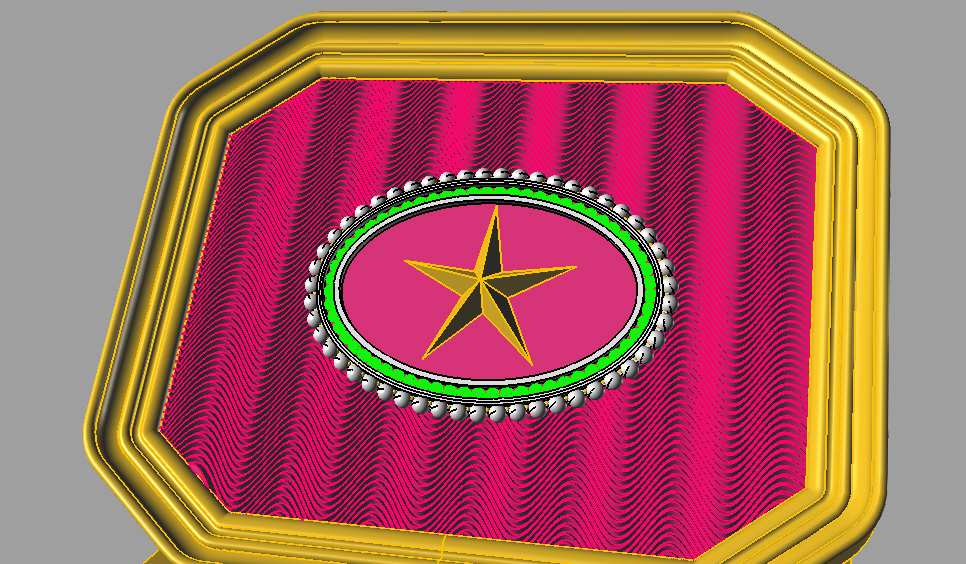

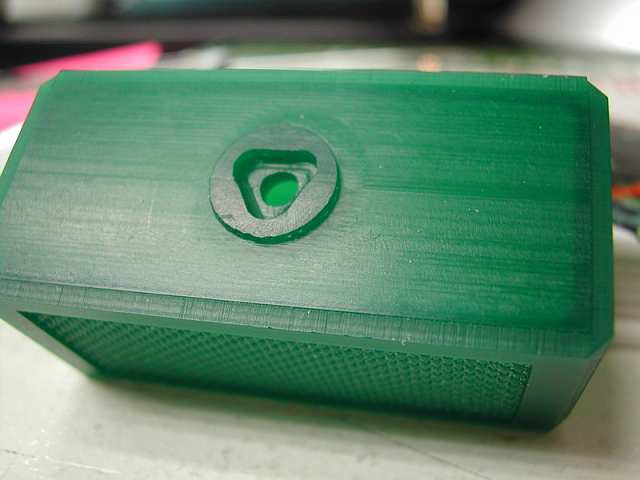

here's one I'm working on I'm going to enter this one in a contest (rendering only) I still have more work to do before it's finished!

| Description: |

|

| Filesize: |

34.26 KB |

| Viewed: |

13260 Time(s) |

|

| Description: |

|

| Filesize: |

84.29 KB |

| Viewed: |

13260 Time(s) |

|

|

|

| Back to top |

|

|

Winstone

Joined: 25 Feb 2004

Posts: 690

Location: Dallas,Texas

|

Posted: Fri Mar 07, 2008 3:29 pm Post subject: wonderful Posted: Fri Mar 07, 2008 3:29 pm Post subject: wonderful |

|

|

Wonderful, I love to see American versions of the guilloche. I hope that my inputs have been of help.

a] Red enamel is a combination of glass and fine gold. I have some transparant red. Thompson enamel sells this enamel.

b] Also if you cut the panels in wax then cast them in fine silver the

lines will come out. You can always recut the lines with your mill. But it must be exact.

c] If in sterling, then you will need to pickle the surface with

either spirex or better dilute nitric acid. ALWAYS ADD ACID TO WATER! if

you do not, it will explode!!

d] After the alloys in sterling have been etched from the surface, then take a glass brush which is made of a lot of glass rods tied together, can be obtained at Stuller, Gesswein, etc.

e]clean surface by first dipping the etched plate into a solution of barcobanate of soda to neutralize acid,

f]then scrub the surface with the glass brush in the direction of the cuts. set item on side after rinsing wit distilled water to avoid spots.

g]Lastly, apply the Thompson enamel mordant on the surface prior to applying the glass enamel.

h] prior to applying the enamel, it must also be cleaned with distilled water then dried prior to use. You can see from my cane handle those small bits of dust that appear in the flat area which shows that I did not clean my blue transparant enamel enough to get a pure blue surface.

i] be sure to use rubber gloves when doin gthe prep, because skin oil will prevent proper enameling and can cause oxides on fine silver surface.

j] Be sure to drill attachement holes prior to enameling for the center medallion to be attached, use two, so that the medallion will always be

centered as you want. We use this trick. We take the screw that we will use, spray it with PAM cooking spray, place wax on the screw and attach this holder to the wax milled medallion propr to casting. This holder is cast with the medallion in Sterling, then when it must be attached, the nut that results from the casting will be tight, when we set up the medallion and screw together the brass screw with a leather washer to protect the enamel, you could use rubber as well. Leather is more traditional.

k] Gold parts are usually plated and added as frames. Unless the box is made of gold, inwhich case it is usually made in 18 karat plumb gold.

l] If you use sterling silver castings it is wise to leave the back unpolished, and counter enamel that surface prior to preparation for enameling the front. Thompson sells a clear enamel to protect the front. It used to be lead glass, but I do not know if it is still sold. I have Guilloche enamels from France which follow the classic formulas. The red enamel will be more to the orange red shade if 18 karat gold is used, because the yellow of the gold will mix with the red of the fine gold mixed with clear glass. True reds come from enamel on fine silver which provides a truly white neutral reflective surface.

In closing, true Guilloche is a time consuming technique, but truly beautiful when done in the classic manner. winstone

|

|

| Back to top |

|

|

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Fri Apr 04, 2008 1:11 pm Post subject: box Posted: Fri Apr 04, 2008 1:11 pm Post subject: box |

|

|

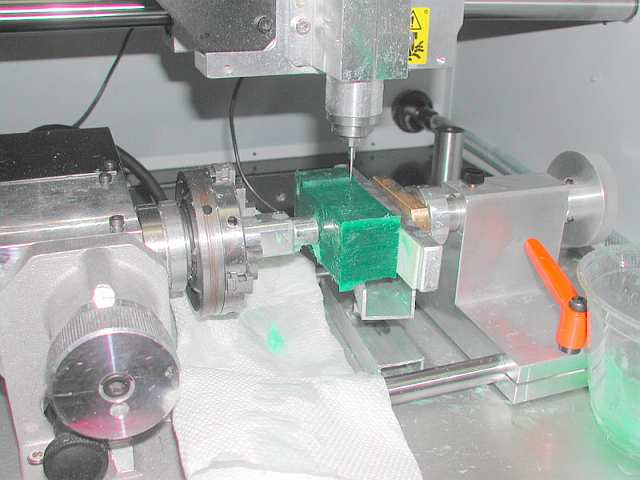

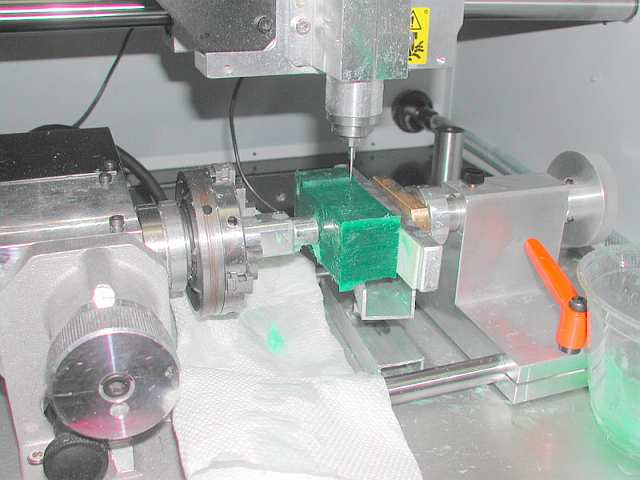

here is a pic of the box being milled ..this is one of the sides being milled the inside of the box has already been milled out.all I have to do is mill the the two end sides to complete you cannot see the detail of the sides in this picture ..will post when completed ..I am using my screw jack for under support and my tail stock for for end support ....I have to rework my tailstock and change it from a "live"center (meaning it will spin) to a "dead" center (meaning it won't spin) then using a system with machinest ball detents to lock it in just enough to stop any spinning movement when milling and still be able to do the rotation when needed it's kind of hard to explain but I will elaborate when I have it finished

I am also using a cutting fluid by "castrol" that has a rust inhibitor in it I got it from my machinest friend I find it's easier than trying to get the mineral oil off the wax now all I have to do is make a dripper

| Description: |

|

| Filesize: |

35.71 KB |

| Viewed: |

13204 Time(s) |

|

|

|

| Back to top |

|

|

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Fri Apr 04, 2008 2:00 pm Post subject: box Posted: Fri Apr 04, 2008 2:00 pm Post subject: box |

|

|

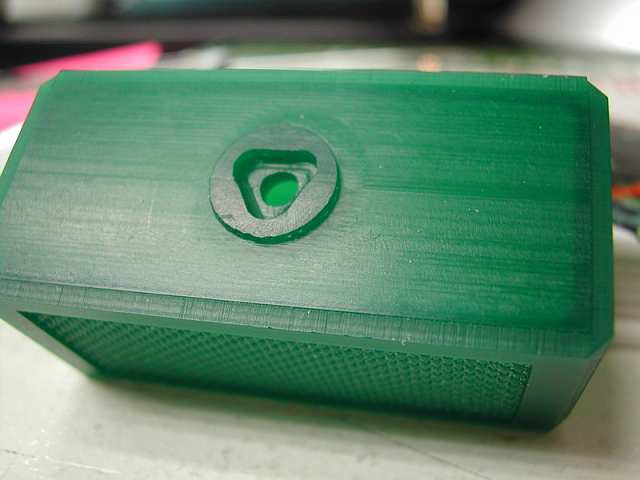

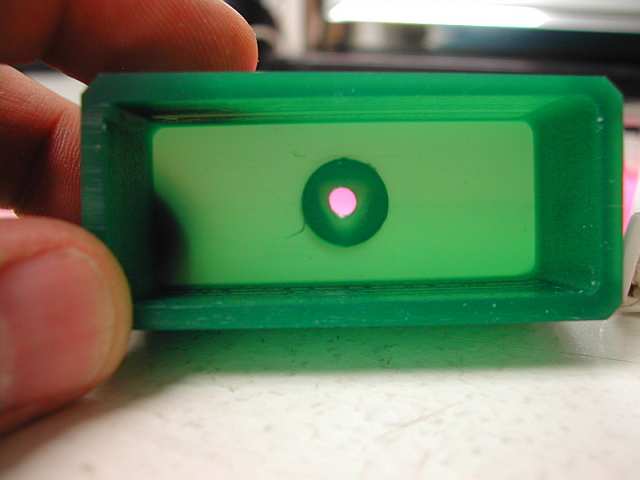

here is the end sides being milled

I used a nut and bolt for the bottom support (bolt has thread tape on it to tighten up the play in the threads) completly adjustable

there is no movement /play in the wax while it is being milled with all these supports

| Description: |

|

| Filesize: |

40.63 KB |

| Viewed: |

13201 Time(s) |

|

|

|

| Back to top |

|

|

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Fri Apr 04, 2008 4:59 pm Post subject: box Posted: Fri Apr 04, 2008 4:59 pm Post subject: box |

|

|

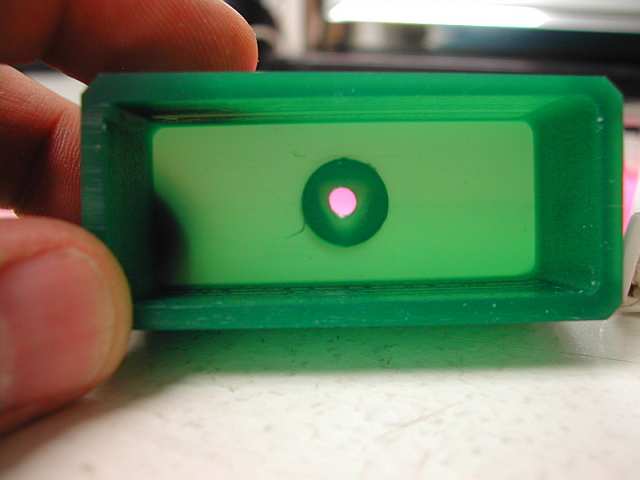

here it is...I know I could have made the outside with more designs to it but this was a rush job for an experiment the next one will be more elaborate all in all it turned out pretty good the bottom has to be sanded smooth as you can see where the taper from the bit cut the edges also I will cut off the core and fill the hole (I know it's not the sqame box as the render that's for later)

| Description: |

|

| Filesize: |

26.98 KB |

| Viewed: |

13197 Time(s) |

|

| Description: |

|

| Filesize: |

21.68 KB |

| Viewed: |

13197 Time(s) |

|

| Description: |

|

| Filesize: |

35.54 KB |

| Viewed: |

13197 Time(s) |

|

|

|

| Back to top |

|

|

jeff dunnington

Site Admin

Joined: 24 Feb 2004

Posts: 1586

Location: Houston, Tx

|

|

| Back to top |

|

|

DPB830

Joined: 03 Dec 2007

Posts: 26

Location: Herrin,IL

|

Posted: Sat Apr 05, 2008 5:39 pm Post subject: Great Job Posted: Sat Apr 05, 2008 5:39 pm Post subject: Great Job |

|

|

That looks Great,Nice job!

|

|

| Back to top |

|

|

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Fri Jun 06, 2008 6:00 pm Post subject: box Posted: Fri Jun 06, 2008 6:00 pm Post subject: box |

|

|

here's my box so far ..had a blow out ...my fault when I remade the center star I didn't make the base thick enough.. so I'll cut out the center and cut a cabochone stone for the center I still have to add the hinge ,gold plate,possibly enammel, and add the pearls ...the top looks bowed but it's just the photo also some of the sprues haven't been cut down yet

| Description: |

|

| Filesize: |

57.94 KB |

| Viewed: |

13050 Time(s) |

|

| Description: |

|

| Filesize: |

50.72 KB |

| Viewed: |

13050 Time(s) |

|

|

|

| Back to top |

|

|

jeff dunnington

Site Admin

Joined: 24 Feb 2004

Posts: 1586

Location: Houston, Tx

|

|

| Back to top |

|

|

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Sat Jun 07, 2008 12:15 pm Post subject: box Posted: Sat Jun 07, 2008 12:15 pm Post subject: box |

|

|

moving right along

| Description: |

|

| Filesize: |

81.56 KB |

| Viewed: |

13042 Time(s) |

|

| Description: |

|

| Filesize: |

75.08 KB |

| Viewed: |

13042 Time(s) |

|

|

|

| Back to top |

|

|

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Sat Jun 07, 2008 12:16 pm Post subject: box Posted: Sat Jun 07, 2008 12:16 pm Post subject: box |

|

|

pg 2

| Description: |

|

| Filesize: |

55.4 KB |

| Viewed: |

13041 Time(s) |

|

| Description: |

|

| Filesize: |

79.67 KB |

| Viewed: |

13041 Time(s) |

|

|

|

| Back to top |

|

|

jeff dunnington

Site Admin

Joined: 24 Feb 2004

Posts: 1586

Location: Houston, Tx

|

|

| Back to top |

|

|

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Sun Jun 08, 2008 8:51 am Post subject: box Posted: Sun Jun 08, 2008 8:51 am Post subject: box |

|

|

| thanks jeff ...I'm using the new anti ox silver from stuller and was wondering about the gold plating.. I know silver will tarnish under the plating so they usually nickel plate then gold plate I heard you can rhodium and it won't tarnish what do you think about just plating with gold since I'm using the anti ox

|

|

| Back to top |

|

|

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Thu Jun 12, 2008 1:38 pm Post subject: box Posted: Thu Jun 12, 2008 1:38 pm Post subject: box |

|

|

here it is ...I had to break out the lapidary equiptment and cut a stone for the center blowout I had ...I used a funny looking blue black stone from australia

| Description: |

|

| Filesize: |

56.19 KB |

| Viewed: |

13002 Time(s) |

|

| Description: |

|

| Filesize: |

43.28 KB |

| Viewed: |

13002 Time(s) |

|

|

|

| Back to top |

|

|

|